Save Half of the Electricity Required by your Dryer!!

NOBODY wants to do laundry, NOBODY wants to spend more money and time doing laundry!

Short and sweet, the answer is to reduce the air resistance of the air exhausting out of your dryer!!

This is done be increasing the size of the pipe used to carry the humid exhaust air from 4 inches to 6 inches. It is almost that simple!!

The little 4 inch vent that exits the building is replaced by a 6 inch one from the Big Box Hardware Store (BBHS). The 6 inch size building vent is normally used as a bathroom vent, you will use it for your dryer.

The 4 inch round duct you have now will be replaced by 6 inch round duct.

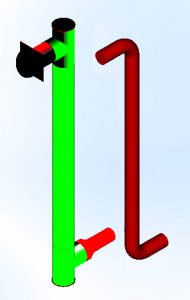

NO elbows will be used, use a 6 inch tee fitting with a cap on one outlet instead of an elbow.

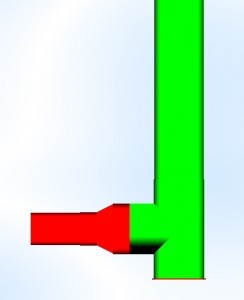

Use a 4 inch to 6 inch duct adapter to increase the duct size as close to the dryer as possible.

Do not use any type of corrugated or flexible duct, only smooth duct, preferably galvanized steel Remember, we want a reduced resistance air flow!!

Thats it!! This increase in air flow will reduce the electricity used (and dryer cycle time) by half.

You are on your way to cutting your electric bill in half!!

Payback could be as little as one month, with continued savings after that.

What are you waiting for, go do it!! The only thing that will happen is you will;

- save electricity

- make your dryer last longer

- make the person that does the laundry happy!!

If you want to read the more technical version of this information go here.

http://www.sweetmk.com/2012/09/cut-your-electricity-usage-in-half-of-your-clothes-dryer/

Leave a Reply